Maison>Produits>Tapered Roller Bearings>Bearing 799A/792 Timken

Bearing 799A/792 Timken 799A/792 Timken MODELS

Need a CAD or 3D Model?

Bearing 799A/792 Timken

Tapered Roller Bearings

Bearing 799A/792 Timken 799A/792 Timken Bearing SPECIFICATIONS

- Bearing 799A/792 Timken

799A/792 Timken

-

Crystal2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Crystal2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Bearing 799A/792 Timken 799A/792 Timken Description du produit

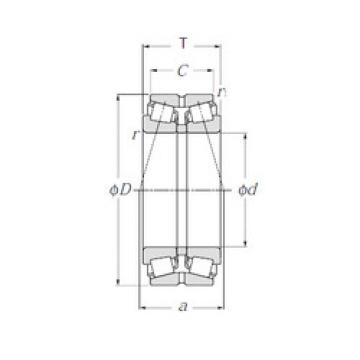

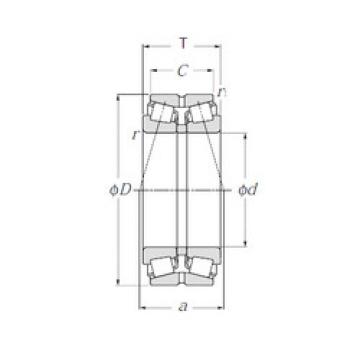

Tapered roller bearings 799A/792

Bearing number : 799A/792

Size mm : 130.175x206.375x47.625

Brand : Timken

Bore Diameter mm : 130,175

Outer Diameter mm : 206,375

Width mm : 47,625

Bearing dimensions and specification in brand catalogue :

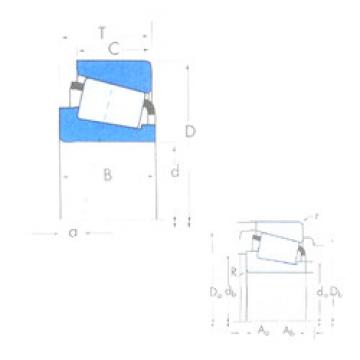

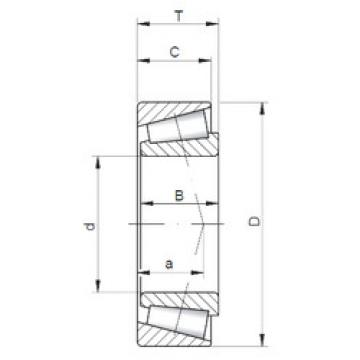

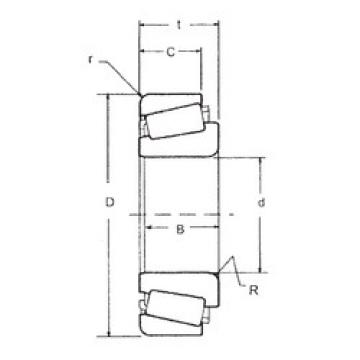

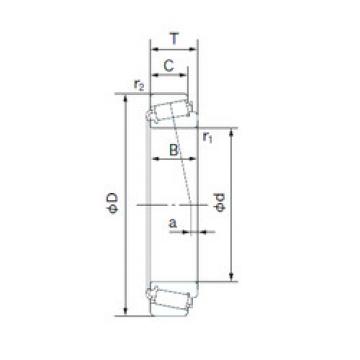

d - 130,175 mm

D - 206,375 mm

T - 47,625 mm

B - 47,625 mm

C - 34,925 mm

R - 3,6 mm

r - 3,3 mm

a - -1,8 mm

Da - 198 mm

db - 148 mm

da - 142 mm

Db - 186 mm

Aa - 5,3 mm

Ab - 2,8 mm

Weight - 5,64 Kg

Basic static load rating C0 - 593 kN

Factor G1 - 326,4

Factor G2 - 62

Factor Cg - 0,0358

Factor K - 1,27

Basic dynamic load rating C90 - 90,8

Basic dynamic load rating Ca90 - 71,3

Basic dynamic load rating C1 - 350 kN

Calculation factor e - 0,46

Calculation factor Y - 1,31

Catalogue,Brandslist,,Bearing 799A/792 Timken

Bearing 799A/792 Timken Shielded bearings have a storage life of five years and a further two years operational life following installation. Wash all bearing parts with a noncontaminating solvent. Lightly pack the bearings with grease applying a 33% fill by volume into the bearing and housings. Where Bearing 799A/792 Timken space heaters are fitted, and the storage environment has wide humi dity and temperature variations, it is strongly recommended they be energised. Warnings should be placed on the Bearing 799A/792 Timken to make operatives aware of the live heaters Supplies are normally 220-240 volt single phase, from a 380-415 volt three phase supply. See terminal box lid for details.

Bearing 799A/792 Timken Shielded bearings have a storage life of five years and a further two years operational life following installation. Wash all bearing parts with a noncontaminating solvent. Lightly pack the bearings with grease applying a 33% fill by volume into the bearing and housings. Where Bearing 799A/792 Timken space heaters are fitted, and the storage environment has wide humi dity and temperature variations, it is strongly recommended they be energised. Warnings should be placed on the Bearing 799A/792 Timken to make operatives aware of the live heaters Supplies are normally 220-240 volt single phase, from a 380-415 volt three phase supply. See terminal box lid for details.

Insulation resistance During extended storage a three monthly insulation test is recommended to avoid possible lengthy drying out periods when installing Bearing 799A/792 Timken. Use a 500 volt d.c. Megger.The insulation resistance between phases and between the windings and the frame should be checked. The insulation resistance should be maintained above 10 megohm. If a lower reading is measured, use one of the drying out methods recommended on page 14 until an acceptable reading is obtained. If heaters are fitted but not energised, they should be used in future. Wound rotors Ideally, wound Bearing 799A/792 Timken brushes should not be in contact with the slip-rings during storage as there is a risk of corrosion. Brushes should either be lifted off the slip-rings or stored separately. This may not be possible with small Bearing 799A/792 Timken.

Insulation resistance During extended storage a three monthly insulation test is recommended to avoid possible lengthy drying out periods when installing Bearing 799A/792 Timken. Use a 500 volt d.c. Megger.The insulation resistance between phases and between the windings and the frame should be checked. The insulation resistance should be maintained above 10 megohm. If a lower reading is measured, use one of the drying out methods recommended on page 14 until an acceptable reading is obtained. If heaters are fitted but not energised, they should be used in future. Wound rotors Ideally, wound Bearing 799A/792 Timken brushes should not be in contact with the slip-rings during storage as there is a risk of corrosion. Brushes should either be lifted off the slip-rings or stored separately. This may not be possible with small Bearing 799A/792 Timken.

Bearing 799A/792 Timken 799A/792 Timken INTERCHANGE

Tapered Roller Bearings Part series 799A/792 Timken is a potential replacement for these common bearing part numbers:

799A/792 Timken

799A/792 Timken

799A/792 Timken

799A/792 Timken

799A/792 Timken

799A/792 Timken

799A/792 Timken

799A/792 Timken

Contactez-nous

- Adresse

- téléphone professionnel(Temps de travail)

- Fax

Bearing 799A/792 Timken 799A/792 Timken Technical Articles

| La gestion et l'entretien de la pompe à engrenages à haute température |

| Commune de failles et de solutions de pompe à boue |

| La cause technique de l’apurement de diamètre de bague et arbre pompe à vis |

Tapered Roller Bearings CATEGORIES

- Tapered Roller Bearings

- parker PV piston pump

- CONTROLLER

- FURNAN PUMP

- Plain Bearing

- Cylindrical Roller Bearings

- PRECISION BALL BEARINGS

- Vickers vane pump

- Bearing catalog

- VICKERS Piston pump

- PRECISION BALL BEARINGS

- Tapered Roller Bearings

- Needle Roller Bearing

- CRUSHER

- POWER TRAIN ASS

- YUKEN vane pump

- TRACK FRAME

- Cylindrical Roller Bearing

- bearing online

- Self-Aligning Ball Bearings

- NACHI piston pump

- REVOLVING FRAME

Customers Who Viewed Bearing 799A/792 Timken 799A/792 Timken Bearing Also Viewed

- Mots clés:

Timken

130.175x206.375x47.625

Bearing 432324U NTN

Bearing 432324U NTN Bearing 430328X NTN

Bearing 430328X NTN Bearing 468/453X ISO

Bearing 468/453X ISO Bearing 67388/67322 FBJ

Bearing 67388/67322 FBJ Bearing 495AX/492A NACHI

Bearing 495AX/492A NACHI